Penstock Repair & Rehabilitation

Penstock Coating with Robotic SIPP Technology

-

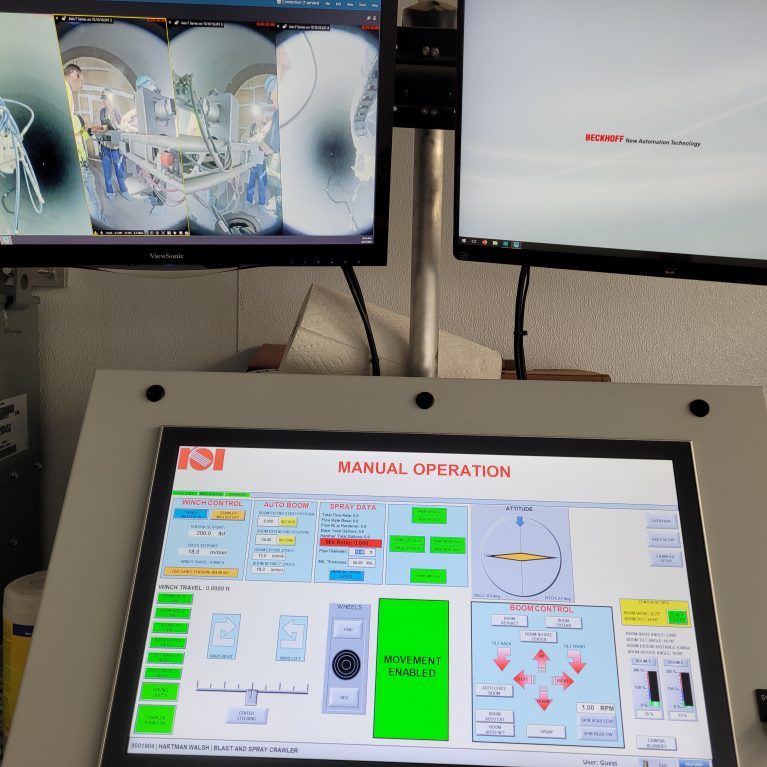

Hartman Walsh has developed and taken to market the industry’s most successful robotic approach to lining large and small diameter penstocks and pipes with epoxy resinous coatings. With over $200M completed and an astounding $100M in backlog specific to this scope, we feel we are positioned to continue leading the industry in SIPP application for hydropower plants and hydroelectric power plants. HW has developed multiple iterations of the robots for varying pipe diameters, configurations, and slopes, including sections of the penstock. We offer an unmanned solution, ideal for confined spaces, which provides zero entry during the surface prep and coatings phase of the project. The work is monitored via a control room, where the computer system runs a continuous loop via fiber optics carried in the umbilical to maintain cart speed in any given section of the penstock, umbilical reel speed, and rotation speed of the arms, while utilizing Coriolis flow meters for maintaining extremely consistent WFT/DFT. This approach ensures cost-effective solutions for extending the service life of steel penstocks, reducing corrosion, and improving environmental protection for power generation facilities.

-

CoatingsPro Magazine – November 2025: Read article

Utilizing this system has also eliminated the large cost of material waste. On a typical SIPP project with manual application, you can expect a waste factor of 15-20% on epoxy resinous linings that are spray applied to diameter penstocks or steel pipes and pipe sections. This loss is typically caused by human error on mil control. With our system, we have dialed our loss down to single digits. This cost-effective solution provides significant cost savings, which can be calculated per square foot once a material and thickness is chosen. HW has the ability to spray epoxy robotically from 6 inches in diameter to 24 feet in diameter, making it ideal for both small and large steel penstocks. R&D and custom engineering/fabrication for confined space applications can also be completed with enough notice.

Work with Hartman Walsh

Penstock Repair Experience

Hartman Walsh Painting Company was established in 1950 and has been successfully providing industrial painting, coating, and lining services to both public and private entities for over 75 years. Our expertise includes work on steel penstocks, hydro projects, and confined space applications, ensuring structures remain in good condition and achieve an extended service life. Hartman Walsh is an SSPC Certified QP-1, QP-2, QS-1 contractor, now recognized under <a href=”https://www.ampp.org/home”>AMPP</a>, and we employ in-house NACE CIP-trained staff to maintain strict quality control. Our services are designed to address corrosion, enhance environmental protection, and provide cost-effective solutions for industrial and hydroelectric power plant projects.

- QP1 – Field Application of Coatings Complex Structures

- QP2 – Industrial Hazardous Paint Removal

- QS1 – Advanced Quality Management System (ISO 9001 compliant)

Hartman Walsh has consistently ranked in the Top 10 List of Largest Painting Contractors in the U.S.A. by ENR, with annual revenues exceeding $80,000,000. We specialize in a variety of applications, including work on steel penstocks, hydro projects, and confined space environments, ensuring high-quality results for our customers. As a national union contractor, our work base consists of 50% Evergreen-type work and 50% lump sum-type work. With 80% of our volume coming from repeat business and an extremely satisfied customer base, we emphasize quality control and long-term service life for the structures we maintain. We currently have projects in progress across North America, including the U.S.A. and Canada, and are eager to travel as required to meet the needs of our customers.

Work with Hartman Walsh

Penstock Repair Safety

Hartman Walsh is committed to safety, and our past performance illustrates the dedication of our employees to providing a safe workplace environment, not only for our own workforce but also for the workforces of our clients. This commitment extends to challenging environments, including confined spaces and hydro projects, where safety protocols are critical. We employ a full-time corporate safety director and provide employees trained in the OSHA 10-hour and OSHA 30-hour programs. Our approach emphasizes forward-looking metrics and KPIs, which are applied across all job sites, including those involving steel penstocks, epoxy applications, and relining projects. This proactive strategy ensures reduced risks, minimizes water infiltration during operations, and supports environmental protection efforts. We have found this approach extremely beneficial in producing consistent, positive results.

Learn more

Quality

As can be seen from some of the previously listed certifications, Hartman Walsh is also very active in the quality area and pride themselves in being able to produce quality results and are committed to right first time performance. We employ a full-time quality assurance manager with active NACE, SSPC, and NAVSEA certifications. In addition to the quality assurance manager, our staff has extensive NACE training, and we employ eight degreed engineers on our team. We believe that this brings further value to the owner with the additional technical expertise and understanding that can be provided during the specification and completion of the work. We are also capable of developing site-specific quality control programs on an as needed basis and have completed numerous jobs where strict quality control reporting has been required. Here are some case studies on existing penstock repair projects.

Learn more

CMAR/Design Build Capacity and Experience

Hartman Walsh has significant experience in working as a design build or construction manager at risk for clients specifically dealing with spray-in-place pipe (SIPP) style projects. HW has executed over 20M USD in CMAR contracts for the lining of large diameter siphons in AZ. These contracts required HW working with the owner to develop the specification and material performance requirements, courting vendors and developing road access for staging and execution of the project. HW has also worked with several private utility owners to develop specifications and outage work plans to ensure that critical path outage dates were met.

Work with Hartman Walsh

Robotic Penstock Repair

Hartman Walsh has developed and taken to market the industry’s most successful robotic approach to lining large and small diameter pipes with resinous coatings. With over 200M completed and an astounding 100M in backlog specific to this scope we feel we are positioned to continue leading the industry in SIPP application. HW has developed multiple iterations of the robots for varying pipe diameters, configurations and slope of the pipe. We offer an unmanned solution which provides a zero entry during the surface prep and coatings phase of the project where the work is monitored via control room, the computer system runs a continuous loop via fiber optics carried in the umbilical to maintain cart speed, umbilical reel speed and rotation speed of the arms while utilizing Coriolis flow meters for maintaining extremely consistent WFT/DFT. Utilizing this system has also eliminated the large cost of material waste, on a typical SIPP project with manual application you can expect a waste factor of 15-20% on resinous linings that are spray applied. This loss is typically caused by human error on mil control, with our system we have dialed our loss down to single digits, this cost savings can be calculated per sqft once a material and thickness is chosen. HW has the ability to spray epoxy robotically from 6 in diameter to 24 ft diameter. R&D and custom engineering/fabrication can be completed with enough notice.

View all industrial painting services.

Work with Hartman Walsh

Contact Us

General Questions:

Call our office at (314) 863-1800 or use the form below.